Low Speed Crusher

Low speed crushers are primarily used to break runners from cold runner molds and feed them back into production in a proportionate manner.

Specifications

-Crushes all types of raw materials with durable and versatile blade designs.

-Recycles crushed material back into production through a proportional valve.

-Features safe, reliable components that meet European standards.

- Achieves high efficiency while keeping dust generation below 0.1%.

-Fully compatible with automation systems, including robots and conveyors.

-Features a noise-reducing design for minimal sound levels.

-Designed for ease of use and maintenance.

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| DDK-250 | 250×240 | 10-15 | 23 |

| DDK-315 | 315×315 | 20-25 | 23 |

| DDK-410 | 410×315 | 25-30 | 23 |

| DDK-420 | 420×350 | 40-50 | 23 |

| DDK-480 | 480×380 | 100-120 | 23 |

Medium Speed Crusher

Medium speed crushers are specifically designed for crushing runners from cold runner molds and thin-walled parts, enabling them to be proportionally re-fed into the production process.

Specifications

-Recycles crushed material back into production through a proportional valve.

-Crushes all types of raw materials with durable and versatile blade designs.

-Features safe, reliable components that meet European standards.

-Less than 1% dust generation with high efficiency.

-Fully compatible with automation systems, including robots and conveyors.

-Features a noise-reducing design for minimal sound levels.

-Designed for ease of use and maintenance.

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| ODK-290 | 282×290 | 30-150 | 140 |

| ODK-310 | 375×310 | 70-150 | 140 |

| ODK-430 | 382×430 | 100-200 | 140 |

High Speed Crusher

Crushing machines with piano type, V type, or flat blades are used in the crushing process with blade models selected according to the material to be crushed. They are suitable for crushing plastic products such as standard sheets, pipes, profiles, and packaging materials.

Specifications

-Imported 62-64 HRC blades; sharp, durable, and easy to replace.

-Fully steel, welded frame; strong and durable construction.

-Capable of easily crushing all types of soft and hard plastics.

-Optional dust separation and automatic feeding system.

-Features safe, reliable components that meet European standards.

-Different cutters and feed opening sizes.

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| GK-400 | 410×235 | 200-250 | 1400 |

| GK-500 | 515×290 | 300-350 | 1400 |

| GK-600 | 615×320 | 350-450 | 1400 |

| GK-700 | 715×320 | 400-500 | 1400 |

| GK-800 | 815×470 | 450-600 | 1400 |

| GK-960 | 960×600 | 600-700 | 1400 |

| GK-1000 | 1000×470 | 600-800 | 1400 |

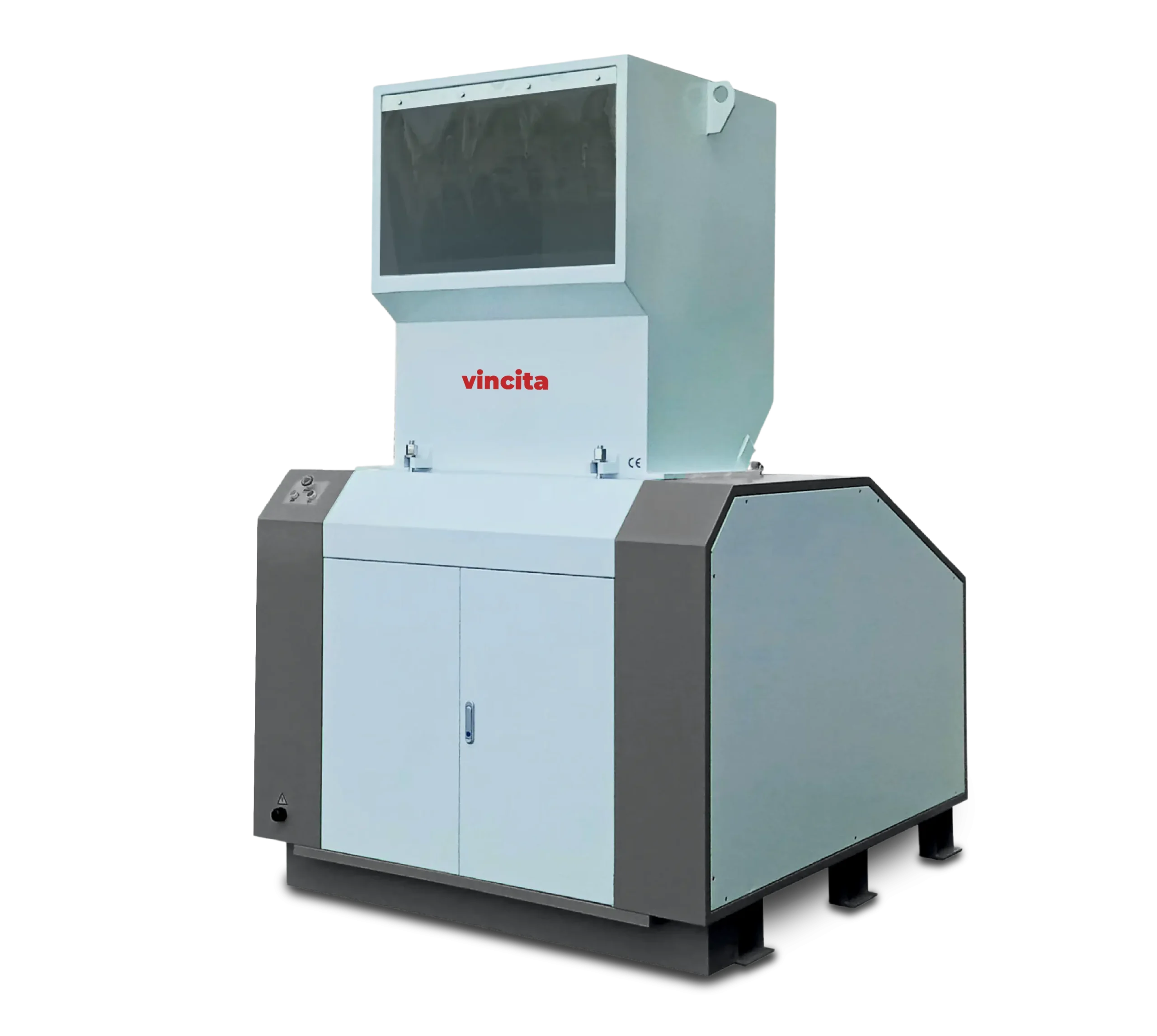

İzolasyonlu Kırıcı

Piano tip, V tip veya düz tip bıçak yapısına sahip izolasyonlu kırma makineleri, kırılacak parçaya göre seçilen bıçak modelleri ile kırma işleminde kullanılır. Sıradan levhalar, borular, profiller, ambalaj malzemeleri gibi plastik ürünlerin kırılması için uygundur.

Specifications

-Imported 62-64 HRC blades; sharp, durable, and easy to replace.

-Fully steel, welded frame; strong and durable construction.

-Capable of easily crushing all types of soft and hard plastics.

-Features safe, reliable components that meet European standards.

-Different cutters and feed opening sizes.

-İzolasyonlu kabin.

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| SGK-400 | 410×235 | 200-250 | 1400 |

| SGK-500 | 515×290 | 300-350 | 1400 |

| SGK-600 | 615×320 | 350-450 | 1400 |

| SGK-700 | 715×320 | 400-500 | 1400 |

| SGK-800 | 815×470 | 450-600 | 1400 |

| SGK-960 | 960×600 | 600-700 | 1400 |

Twin Shaft Shredder

Shredder machines, which provide a solution for crushing large blocks, thick pieces, various plastics, and solid or hollow objects to be reintroduced into the process, can be selected according to different needs and capacities.

Specifications

-Imported blades with 62-64 HRC hardness; high durability and easy to replace.

-Optional mesh sizes, dust separation, and automatic feeding system.

-Features safe, reliable components that meet European standards.

-Capable of easily crushing all types of soft and hard plastics.

-Different cutters and feed opening sizes.

-Design that facilitates easy cleaning and maintenance.

-Strong and durable construction.

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| CSS-600 | 690×500 | 400-600 | 83 |

| CSS-800 | 900×900 | 800-1000 | 83 |

| CSS-1000 | 1000×1200 | 1000-1200 | 83 |

| CSS-1200 | 1200×1500 | 1200-1500 | 83 |

| CSS-1400 | 1500×1600 | 1500-1800 | 83 |

Single Shaft Shredder

Technical Parameters

| Model | Throat Size(mm) | Crushing Capacity (kg/hour) | Rotor Speed (rpm) |

|---|---|---|---|

| TSS-600 | 560×680 | 400-600 | 83 |

| TSS-800 | 760×800 | 800-1000 | 83 |

| TSS-1000 | 960×1000 | 1000-1200 | 83 |

| TSS-1300 | 1160×1200 | 1200-1500 | 83 |

| TSS-1300 | 1160×1200 | 1200-1500 | 83 |

© 2025 Vincita Plastik. All rights reserved.